Phoenix Controls Valves

Additional Information

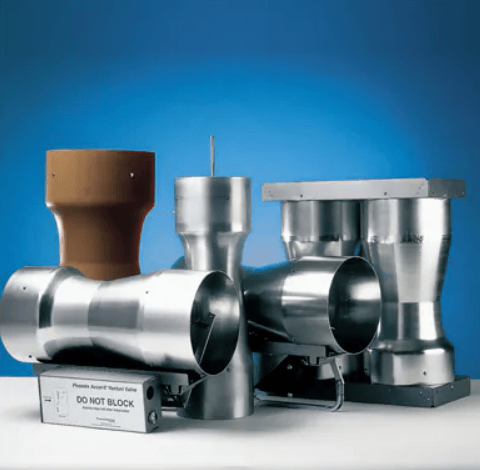

Valves

Owners of facilities with pressurized spaces typically find their spaces do not operate as they were designed to. The most common issue is poor airflow control that can cause safety concerns, energy waste and potential research integrity or production loss. Poor airflow control can be caused by many factors, including:

- Installation issues caused by duct runs that are not as straight or as long as required

- Slow speed of response due to measuring delays

- Instability due to pressure variation

- Sensor drift requiring frequent recalibration

- Unbalanced airflow demanding additional balancing / commissioning work

- Clogging of sensors necessitating periodic maintenance

Poorly performing pressurized spaces drive a facility’s utility costs higher than it needs to be. Many research universities find that anywhere between one half and two-thirds of their annual utility expenses is spent on their laboratory buildings. Facility owners need a more accurate airflow control solution that allows them to safely maintain their pressurized spaces while lowering their utility spend.

The solution is a pressure independent flow metering valve such as the Accel® II venturi valve by Phoenix Controls. The Accel® II venturi valve is the most accurate airflow control valve in the market today. There are multiple reasons for its high degree of accuracy including:

- Utilizing flow metering technology that does not need long duct runs or use a K factor to correct for errors

- Has a one second speed of response which valves requiring flow measurement cannot match due to inherent signal latency between flow sensor, controller and actuator

- Pressure independent due to its use of a cone assembly that maintains flow with changes in static pressure

- Pressure independence eliminates the “hunting” that is typical of airflow control valves that use flow measurement for control

By maintaining precise pressurization the Phoenix Control Accel® II valve ensures the minimum amount of airflow is used. By minimizing air change rates owners can achieve energy savings while also ensuring safety.

With over a million control valves installed worldwide, and sales and support staff that averages over 15 years of experience, Phoenix Controls is by far the leader of maintaining pressurized spaces for critical applications.